At Moss, we are revolutionising the SEG (Silicone Edge Graphics) fabric industry with our innovative Fast Lane production flow.

Optimising the entire production process, enhances efficiency from order entry to product completion – significantly reducing lead times and improving sustainability. By automating the pre-flight process, which previously consumed 80 percent of the production time, we achieve quicker throughput and set a new standard in the industry.

DEDICATED RESOURCES AND EQUIPMENT

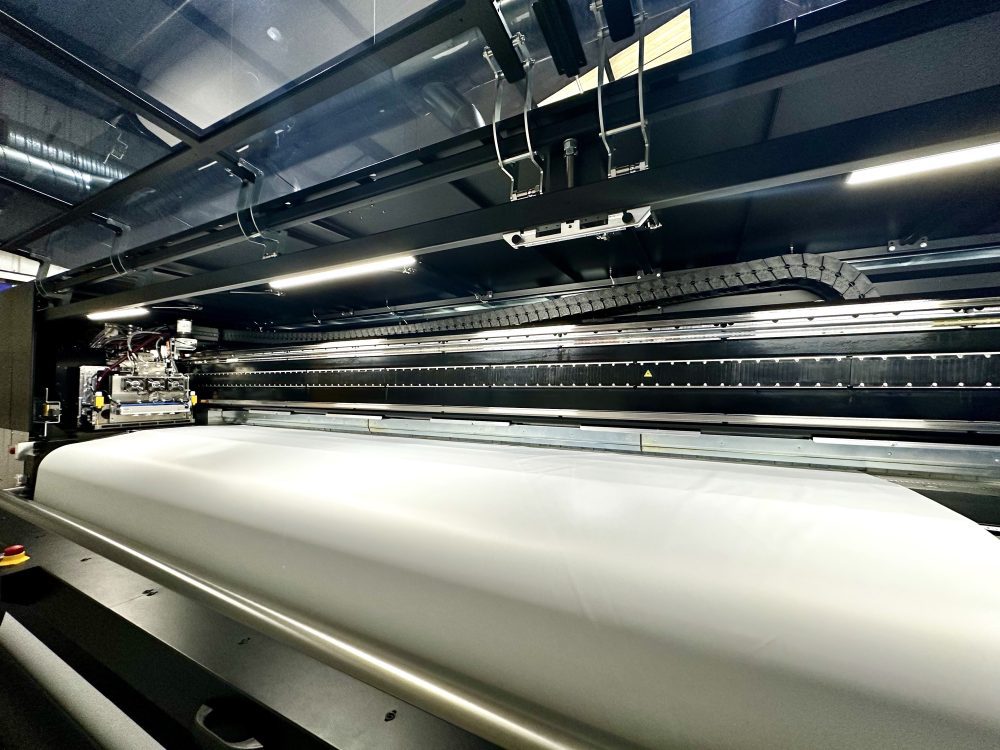

A cornerstone of our optimisation strategy is the acquisition of the right equipment, whether semi-automated or fully automated, to ensure consistency and efficiency. For example, in the US we now stitch non-PVC gaskets using semi-automated equipment and, in the UK, we have invested in specialist printers such as the Durst P5 500 which now sits alongside our P5 TEX iSUB which was installed in 2022.

Our strategic placement of specialised printers near key production areas enables us to process orders rapidly. This proximity allows for immediate printing of SEG fabrics as soon as an order is received, significantly reducing the time taken to move materials between different stages of production. By minimising these delays, we can ensure that each stage of the production process flows seamlessly into the next, resulting in faster turnaround times for our customers.

In the US, our enhanced production capability allows us to handle 300-400 SEGs daily with a two-to-three-day turnaround, a remarkable improvement from the four-to-seven days required pre-COVID.

STREAMLINING THROUGH AUTOMATION

Our automation tools have not only streamlined the process, enabling us to handle large volumes of graphics with minimal manual intervention, but they have also helped manage labour challenges. For example, our new automated sewing machines are crucial for training and onboarding staff, accommodating varying daily production demands. In addition, we have also invested in two new sewing machines to increase the range of materials we can work with. By allowing our staff to focus on critical tasks, with the best machines, we have greater capacity and a smoother workflow to work to the deadlines our customers’ demand.

We understand the importance of maintaining consistent environmental conditions for material testing and quality assurance. Our global approach to testing materials allows us to share resources and knowledge across our locations in Germany, the UK, Poland, and the USA. This rigorous testing ensures that our products meet the highest standards of quality and performance around the world. By maintaining optimal conditions for humidity and temperature, we ensure that our SEG fabrics are consistently reliable and fit for purpose.

REDUCING LEAD TIMES AND ENHANCING ORDER PROCESSING

In Germany and Poland, the integration of Easy Order Print with our SEG Fast Lane system allows customers to order backlit, blockout, and base fabric products online for next-day delivery when ordered before 1pm. This has reduced the average lead time to less than two days. The consistent use of materials and setups across different locations has shared learning across Moss to enhance collaboration and deliver improved service for our clients.

Automation plays a vital role in reducing touchpoints, simplifying the order process, and avoiding miscommunication. The seamless integration between our Customer Portal, Easy Order Print and Moss OS ensures a paperless workflow from order entry to production, further expediting the process.

The Fast Lane system has transformed our approach to order processing, enabling us to meet tight deadlines with remarkable efficiency. Our streamlined digital workflow eliminates the need for manual data entry and reduces the risk of errors, ensuring that orders are processed quickly and accurately.

A FOCUS ON SUSTAINABILITY

Our ongoing focus on sustainable practices and materials underscores our commitment to environmental responsibility – as evidenced by the recent launch of SustainaTex Ocean in the UK from its initial development in the US. Sustainability and efficiency are at the forefront of our operations, and we strive to minimise waste and maximise productivity through practices like nesting images to reduce fabric waste.

Seasonal slowdowns are utilised for research and optimisation, allowing us to analyse trends and capacity to meet demand while maintaining lead times. Meanwhile our ongoing analysis of trends and capacity is crucial for adapting to market demands and ensuring that we can meet them efficiently. By continuously monitoring these factors, we can make informed decisions that enhance our production capabilities and maintain our competitive edge.

THE FUTURE IS BRIGHT

We are excited to focus on further optimisation, particularly in sewing automation for the UK site. By reducing stress on stitchers and addressing bottlenecks in cutting and stitching processes, we can continue to deliver a more efficient workflow and helping reduce lead times while giving customers the high-quality product that they have come to expect of Moss.

Learn more about SEG Fabric and Frames and our Sustainable Practices.

UK - English

UK - English US - English

US - English EU - German

EU - German EU - Polish

EU - Polish ES - Spanish

ES - Spanish