PRODUCTION

OUR

PRODUCTION

HUB

Branded Experiences, Built Better.

EVENTS

Transform your event with our graphics, signage, and custom fabrication solutions. From tension fabric structures for brand activations to large format signage for sporting events, our team can bring your vision to life.

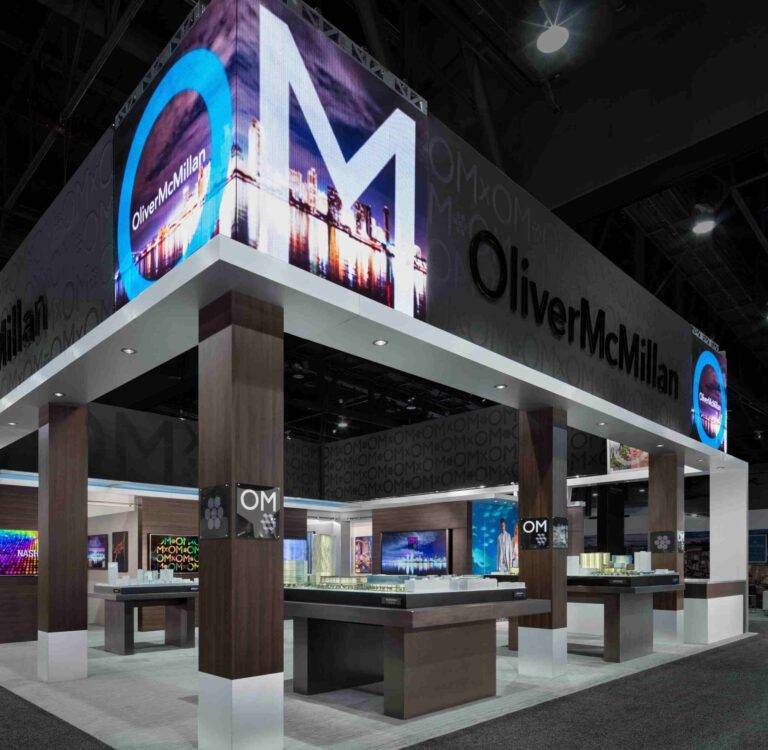

EXHIBITS

As a recognized leader in the fabrication of tension fabric structures, our fabrication experts use proprietary solutions to ensure that your exhibits and will be a unique and impactful experience for all involved.

ENVIRONMents

Our project management, manufacturing and installation capabilities make your concepts a reality. We collaborate to create functional branding for corporate offices, museums, healthcare and educational environments.

RETAIL

Our experts handle every aspect of manufacturing from technical design and graphic layouts, to prototyping and production, all the way through to final installation. We are a single-source partner to execute your branded in-store experiences.

Everything under

one roof

We are uniquely positioned to offer a truly in-house print, production, and finishing facility, covering 50,000 square feet and equipped with state-of-the-art machinery. Our extensive capabilities enable us to efficiently handle large projects with quick turnaround times, all within one cohesive location.

Our

Global Manufacturing

The equipment we use significantly impacts our production, so upgrading our machinery involves critical decisions. Our latest acquisitions, including the Nyala Swiss Q, Durst P5 iSub and Durst P5 500 were chosen based on the following considerations: Energy consumption, connectivity, automation and quality or output vs speed of production.

The ink we use is equally important, we only use manufacturer-recommended inks, all of which are Green Guard Certified and hold the Nordic Swan Certification. Additionally, any waste ink is responsibly recycled back as waste-to-energy through approved sources.

Colour Management

YOUR PARTNER IN

Order Management

YOUR

ORDER MANAGEMENT

PARTNER

Your

order management

made easy

At Moss, we continually invest in technology to enhance efficiency and service for our clients. Our LIFT system provides clients with direct access to their projects, enabling them to easily monitor progress, approve artworks, and much more. The LIFT Enterprise Resource Planning (ERP) system allowed us to manage project effortlessly from any mobile device or computer, providing real-time progress tracking.

Benefits for our clients:

- Access to Orders: Clients can easily view and manage their orders.

- Proof Approval: Simplified process for approving proofs.

- Comprehensive Project History: LIFT stores the history and artwork of each project or campaign, assisting with future planning.

Our goal is to give our clients greater control, improved visibility, and make managing projects easier and more efficient.

Colour

Management

Our diligent colour management ensures the depth of colour, vibrancy, and consistency of our graphic production is well above the industry standard providing our clients with the best possible solution across a variety of print media.

Our continued investment in technically advanced printer combined with the expertise and technology of our pre-press studio carefully monitors colour and resolution issues. Our colour control booth allows accurate colour matching essential for retail campaigns when matching to previously printed examples.

Our

Services

Explore our wide range of services and see the many ways we can help support your requirements.

Create

Branding Solutions

Lightbox Displays and Graphics . Innovative Brick-Wrap Vinyl Technology . Large Format Printing . Hoardings . Building Wraps . Glass Manifestations . Heras Fence Branding .

Activate

Brand Promotions and Activations

Exhibition Stands . Tension Fabric Systems . Campaign Graphics and POS . Window Displays . Event Branding . Wall Coverings .

Inform

Wayfinding and Signage

SEG Fabric and Frames . Tension Fabric Rental Products . Signage . Wayfinding . Banners . Floor Graphics .

VIEW OUR SUSTAINABLE BRANDING Solutions

WORK WITH MOSS

AROUND THE WORLD

NORTH AMERICA

EUROPE