How Our Weekend Crew Keeps Production Moving

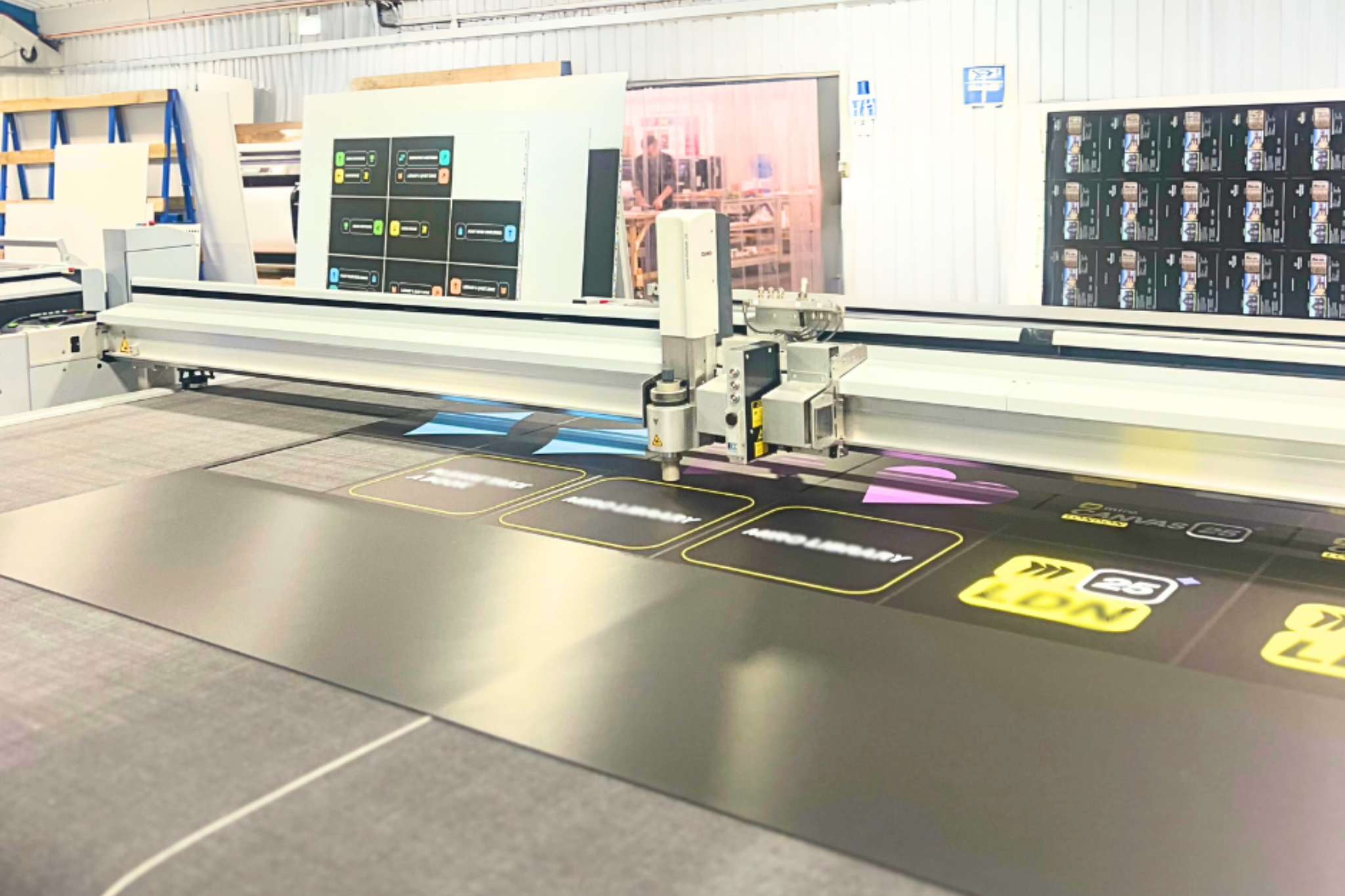

At Moss UK, our goal is to create a production environment that is efficient, responsive, and supportive of the dedicated people who keep it running. One of the ways we do this is through our split-shift working pattern, with a structure that allows us to maintain momentum all the way through the weekend while supporting a healthy work-life balance for our weekday teams. By spreading our production capabilities across seven days, we’re able to remain agile, and deliver a consistency high level of service to our clients.

We have moved to this split-shift pattern recently due to further understanding of our client base and engagement with them to provide a more rounded production facility. This change helps us better match production capacity to client demand and maintain a smoother, more consistent workflow throughout the day. Also, with further investment planned for 2026 in both machinery and staff levels, we are aiming to further improve efficiency, increase capacity and strengthen the overall quality of our service.

Currently, our split-shift model runs from Friday to Monday, with 5-hour shifts on Fridays and Mondays and 12-hour shifts on Saturdays and Sundays. This schedule is further supported by the flexibility to adjust hours around business needs, ensuring that we can always react quickly to any fast-moving client demands, particularly those that may come in last-minute over the weekend. This level of adaptability is essential in a production environment where deadlines can shift rapidly, and client expectations continue to grow.

The weekend crew itself is made up of seven skilled team members, each playing a role across different areas of production. Their combined expertise ensures that even during traditionally quieter periods, we’re able to maintain a smooth and continuous workflow. As we continue to analyse the evolving demands of the business, we anticipate this group expanding, therefore strengthening our support during busy periods and helping to improve the overall production flow across the facility.

This approach doesn’t just keep the production hub running smoothly; it makes the entire company operate more efficiently. Our Head of Production, Jason Arnill, explains, “By concentrating weekend production we’re able to gang up materials more effectively, reduce waste, optimise run lengths, and significantly improve turnaround times. It also means that our weekday teams return with the rest they need, resulting in better focus, improved speeds, and fewer internal errors.” All of this contributes to the high service levels that our clients expect from us.